3” Diameter Cartridge Spindles.

DESIGNED FOR HEALD MACHINE MODELS 70, 70A, 72, 72A, 75, 75A, AND 271, 272,

273A, 274, 275, 276, 280, 280A, 281, 290, 290A, 291, 170A, 180A, AND 190A.

Fits Okamoto IGM-2M and IGM-15CNC.

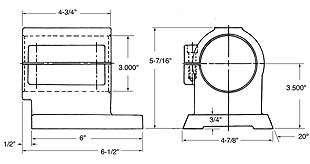

Fits Heald machine models 70, 70A, 72, 72A, and 75A requiring a 3" center line distance from the base. Unit weight 14.15 lbs.

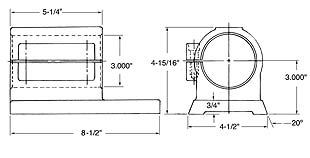

Fits Heald machine models 271, 272, 273A, 274, 275, 276, 280, 280A, 281, 290, 291, 170A, 180A, 280A, 281, 290, 291, 170A, 180A, and 190A requiring a 3-1/2" center line distance from the base. Unit weight 13 lbs. Fits Okamoto IGM-2M and IGM-15CNC machine models.

01246

01178