Internal and External Grinding.

THREE BEARING DESIGN PROVIDES MAXIMUM VIBRATION DAMPENING FOR ID GRINDING.

INSERTS AND ACCESSORIES ALLOW YOU TO DO BOTH OD AND ID GRINDING.

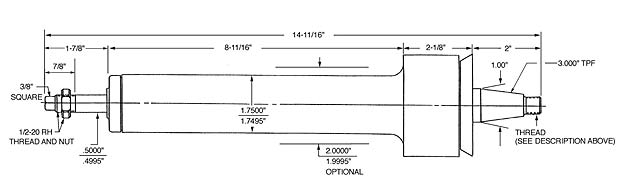

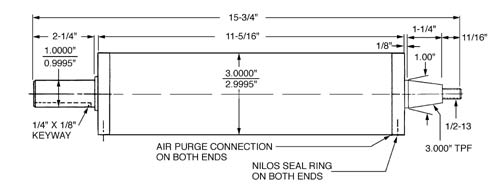

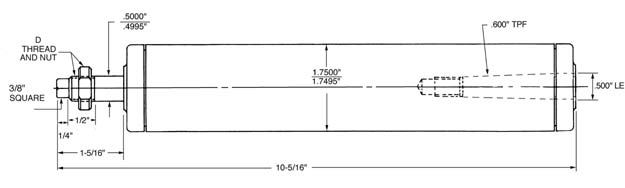

HEAVY DUTY REPLACEMENT SPINDLE FOR SERIES 5, 55, AND 57 DUMORE TOOL POST GRINDERS. ALSO IDEAL FOR CUTTING COMMUTATORS, ARMATURES, AND CARBIDE.

- Made with ABEC 7 precision bearings.

- 32,500 RPM maximum.

- Grease sealed lubrication allows for horizontal or vertical operation.

- Duplex wheel end bearing. Two precision matched bearings spaced for optimum rigidity. Duplex bearings eliminate end-play and prevent movement at the wheel end of the spindle.

- Spindle assembly dynamically balanced for smooth operation at all spindle speeds.

- Spindle housing machined from solid bar stock for rigidity even after thousands of hours of operation.

- Nilos rings on bearing races help keep out dirt, abrasive particles and coolant, and hold grease in bearings by forming a complete labyrinth seal prolonging bearing life.

- Maximum spindle runout .0001 T.I.R.

- Floating pulley end bearing floats against spring tension to permit thermal expansion of the shaft.

- Unit net weight 5.15 lb. Shipping weight 6 lb.

01247

CATALOG NO.

PART NO.

See our complete line of accessories on page 103 and 104.