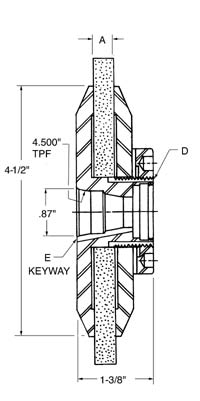

Cincinnati Taper Flanged

and Cup

Wheel Extension Adapters.

4.500" TPF WITH .87" DIAMETER AT LARGE END OF TAPER. FOR

1.250" ID WHEELS. USED ON ALL CINCINNATI NO. 1 AND NO. 2 SPINDLES,

COVEL, AND GALLMEYER & LIVINGSTON CUTTER GRINDERS; OR ANY SPINDLES

WITH .87" DIAMETER AT LARGE END OF TAPER AND 4.500" TPF.

Sopko flanged adapters are machined from forged alloy steel. The resulting one-piece hub design distributes mounting pressures away from the bore, the weakest part of the grinding wheel. The inherent rigidity of one-piece design and the precision ground flange provides identical radial load-bearing surfaces for positive wheel lock and better spindle driving torque to the abrasive wheel. All surfaces are ground concentric and square for optimum surface finishes. Completely heat treated, Sopko flanged adapters are safe to use and maintain their rigidity.

CATALOG NO.

PART NO.

C4.5-1

C4.5-1KW

C4.5-2

C4.5-2KW

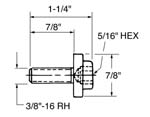

*Spindle mounting bolt 14362 and retaining ring 04269 included.

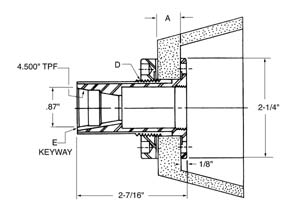

Sopko cup wheel adapters are made with a THIN-WALL FRONT FLANGE design to give maximum usage of cup wheel depth. Fully HEAT TREATED, and made from SOLID BAR STOCK, Sopko cup wheel extension adapters are RIGID to provide positive lock. A hardened nut locks the wheel from the back of the adapter. Because of this nut configuration, RH threads are used for CW spindle rotation and LH threads are used for CCW rotation; providing a safe locking system that WILL NOT LOOSEN during spindle rotation.

00290†

CATALOG NO.

PART NO.

C200-2CW

C200-2CWKW

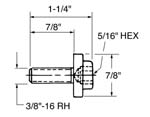

** Includes spindle mounting

bolt 14362 only.

†Grinding wheel not included.